The Persistent Challenge: Ensuring Reliable Data Entry

After deploying and running the TilliT platform across multiple domains for the past five years, we identified several key obstacles to implementing end-to-end traceability in enterprises. These challenges were observed in diverse industries, including:

- Agri (Organic)

- Agri (Inorganic)

- Alcohol

- Textiles

- Fashion

- Gems

Among these, tracking data entry emerged as the most significant challenge.

To generate traceability information downstream, enterprises must track data at all critical stages of the value chain. This involves both entering data and accurately linking it to the correct batch. Unfortunately, manual tracking comes with several disadvantages:

- High Labor Costs: Manual data entry is labor-intensive and expensive.

- Error-Prone Processes: Human errors often lead to inaccuracies in data entry.

- Staff Turnover: High attrition rates among blue-collar workers result in frequent staff training requirements.

- Low Incentive: Workers see tracking data entry as extra work with no direct benefits to them.

- Limited Trust: Some companies hesitate to let field and floor workers enter data visible to external stakeholders.

- Digital Literacy Gaps: Workers often lack the necessary digital skills to perform tracking tasks effectively.

Data Tracking Approaches we have followed so far

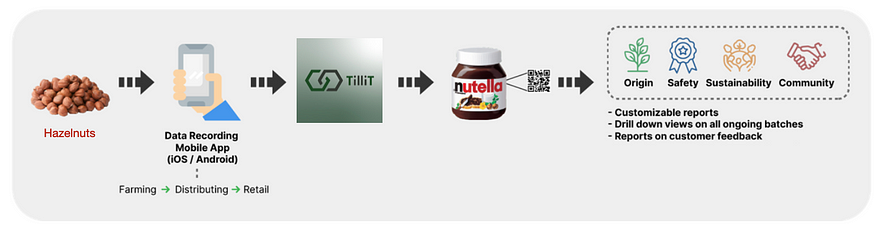

TilliT Classic offers three modes of tracking data entry:

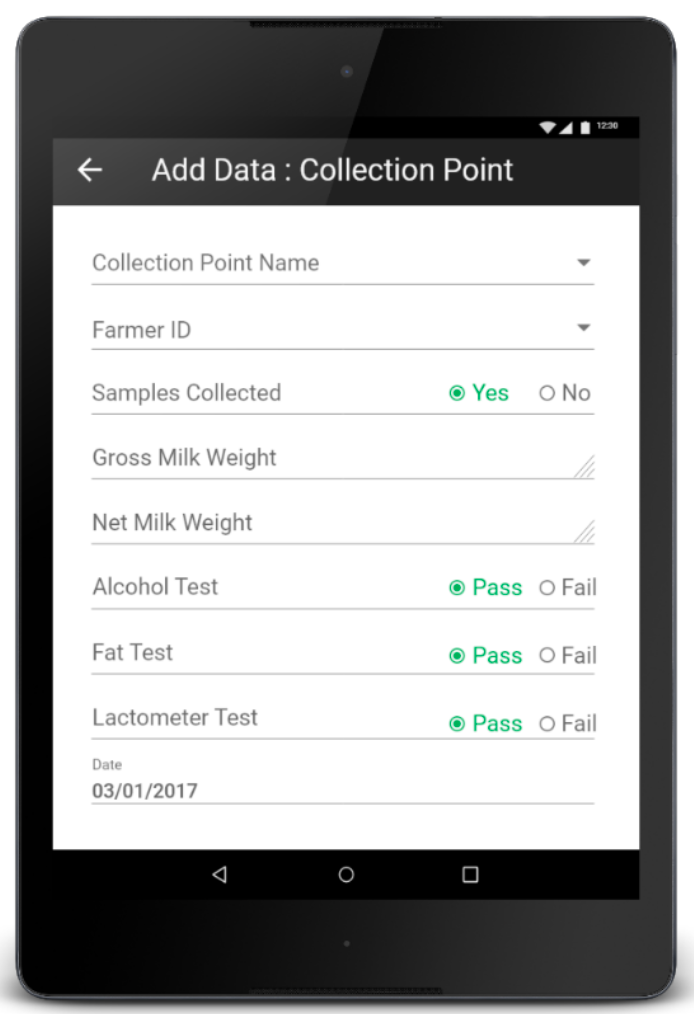

- Manual Entry via Mobile App: Workers use a mobile app to enter tracking data (including geo-coded and timestamped images) for their stage in the supply chain.

- Integration with Existing Systems: Importing data from existing digital data sources such as ERP and SCM systems.

- Sensor-Based Tracking: Automating supply chain tracking via sensors.

However, these methods face limitations:

- Manual entry is prone to the challenges listed above.

- ERP and SCM systems often lack comprehensive traceability data, as they are designed for different purposes.

- External integrations are expensive to set up and maintain.

- Many supply chains are not equipped to handle advanced sensor systems due to high costs and logistical barriers.

AI as the Game-Changer for Automated Data Entry

In practice, batch-related data in most supply chains is stored in Excel sheets or even on paper, making it difficult to integrate into a digital traceability system. This is where AI becomes transformative.

Here’s how AI can address the data entry bottleneck:

1)OCR for Digitizing Paper Records:

Layout-preserving OCR solutions can convert physical records into digital formats while keeping the meaning of data intact. This applies well for a multitude of document types such as purchase orders, invoices, goods receival notes, certifications, product catalogues, ESG documents, etc. Data modelling for each of the anticipated document types is a prerequisite here.

2)NLP for extracting information out of unstructured data:

A vast majority of documents found in supply chains are unstructured (follows arbitrary formats). Even the structured data such as excel sheets do not have their columns predefined. While applying common NLP techniques to deal with some of the complexities, the modern LLMs such as OpenAI’s GPT and Anthropic’s Claude can be used widely for extracting data related to products, materials, processes, etc. LLMs, when used in conjunction with appropriate abstract representations of the entities and relationships involved, turn out to be very powerful in extracting relevant information from documents with unknown formats and multiple languages.

3)Web Scraping for Public Data:

Since the document upload is an ad hoc operation, not all the required information may be found in the uploaded documents. Web crawling and scrapping can be used to find some of the missing information such as the contact information of a person, the address of an organization or extended information about a material.

4)Augmenting extracted information with the common knowledge of LLMs:

Since LLMs are trained with a large fraction of knowledge from the world wide web, they potentially carry information related to the entities involved in a given supply chain. For an example, if a supplier carries a certification, the LLMs can be used to figure out what kinds of ESG claims the supplier’s products are entitled to, such as gender equality, vegan or fair trade, benefiting the buyers downstream.

The Future of Supply Chain Traceability

By integrating AI at the data entry stage, traceability platforms can minimize demands on existing business processes, ensuring sustainability and scalability. AI-driven automation not only reduces errors but also empowers supply chains to embrace transparency without incurring prohibitive costs.

At TilliT, we are harnessing the power of AI to overcome the most significant hurdle in supply chain traceability: accurate and efficient tracking data entry. The result? A more transparent, efficient, and sustainable supply chain ecosystem.

About The Author: Admin

More posts by admin